IVM – Innovative Vibration Monitoring is an innovative SME, dedicated to develop end-to-end monitoring & diagnostics systems, mainly focused on wheel/rail interaction, both in static and in dynamic conditions.

During rail operation, several deviations from the initial set-up of the optimal parameters can arise at the wheel/rail interface. Consequently, it’s possible that abnormal mechanical stresses can occur, the wear of the components accelerates, the energy consumption increases and more importantly, running safety can be lost in the worst cases.

Being aware of the forces in play generated at the wheel-rail interface is fundamental because it can provide information both on the infrastructure and the rolling stock status. Continuous monitoring over time of the multiple phenomena related to the wheel/rail interaction allows the rail operators to simply and efficiently maintain the optimal parameters. Consequently, they benefit from both predictive and on-condition maintenance approaches. Thanks to a multidisciplinary know-how, IVM is able to develop the entire measuring chain of its systems that allows the most advanced performances, equipped with specific technical architectures, that are the key condition for both predictive and on-condition diagnosis.

The main objective is to obtain usable information and not just “data”.

Awards

-

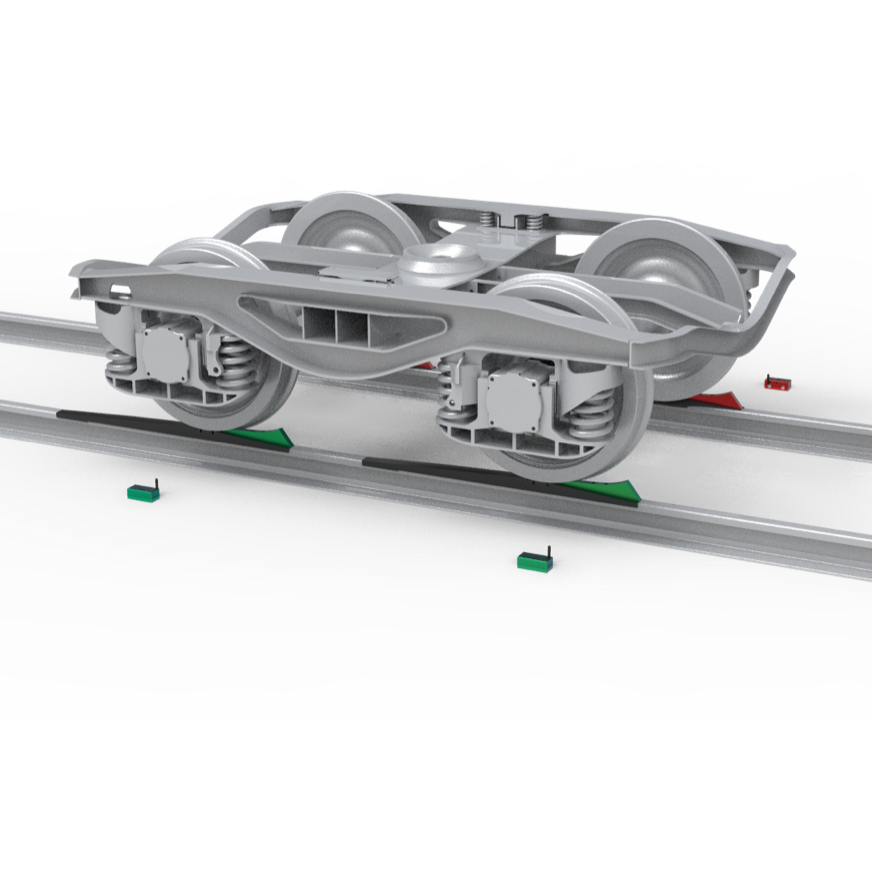

POWERVEAn innovative system to determine the actual weight transferred from each wheel to the rail

POWERVEAn innovative system to determine the actual weight transferred from each wheel to the rail -

-

OCTOPUSThe system is designed to monitor the wheel/rail interaction by measuring the accelerations of the train while running

OCTOPUSThe system is designed to monitor the wheel/rail interaction by measuring the accelerations of the train while running -

-

VAMS-UBMMeasurement of vibrational waves transmission by means of instrumented antivibration mats

VAMS-UBMMeasurement of vibrational waves transmission by means of instrumented antivibration mats