MEASUREMENT

OF VERTICAL FORCES

ON WHEELS AND WHEELSETS:

FINALLY EASY, FAST,

ANYTIME & EVERYWHERE!

POWERVE®

portable weigher for railway vehicles

The right distribution of the vertical forces, that each wheel statically loads on the track, is a key-factor to ensure the dynamic stability of any rolling stock and avoid abnormal wear in wheel/rail interaction. Unloaded wheels, especially on the diagonal side of a bogie, can significantly decrease the capacity of the bogie to safely run on twisted tracks, increasing derailment risk.

Correct balancing of rolling stock is, in fact, an essential requirement for running safety, as also reported in Directives (EU) 2016/797 (on the interoperability of the railway system) 2016/798 (on railway safety) and in Regulation (EU) No. 1302/2014 (Technical specification for interoperability relating to the ‘’rolling stock — locomotives and passenger rolling stock’’ subsystem – TSI LOC & PAS). The balancing of the rolling stock must therefore be guaranteed during the entire useful life of the rolling stock. In particular, the TSI LOC & PAS specifies that:

- Wheel load:

§4.2.3.2.2: ” The ratio of wheel load difference per axle Δqj= (Ql-Qr)/(Ql+Qr), shall be evaluated by wheel load measurement, considering the load condition ‘design mass in working order’. Wheel load difference higher than 5 % of the axle load for that wheelset are allowed only if demonstrated as acceptable by the test to prove safety against derailment on twisted track[…]”

The method of verification and monitoring of this essential requirement is delegated to EN 15654-2 ”Railway applications – Measurement of vertical forces on wheels and wheelsets – Part 2: Test in workshop for new, modified and maintained vehicles”.

It is usually needed a high performance fixed weighing system to meet the requirements of the EN 15654-2. Unfortunately the right fixed system is not always easy to find nearby and moving a rolling stock vehicle to a fixed weighing system can be expensive too.

POWERVE®, the most innovative static measuring system of vertical forces per wheel, transforms any rail into a measuring station with very high precision and accuracy characteristics that allows you to carry out weighing tasks quickly and easily.

POWERVE® is a measuring instrument certified by ITALCERTIFER (ref. Assessment report ITCFC-19222-11-ATF-RA-00011), in compliance with the following standards:

– EN 15654-2:2019 ”Railway applications – Measurement of vertical forces on wheels and wheelsets – Part 2: Test in workshop for new, modified and maintained vehicles”

The ideal solution for

- Testing & Commissioning of new, maintained or modified rolling stock compliant with the EN 15654-2 and EN 50215

- Workshop or in-field maintenance

- Suspension load adjustment to equalize vertical forces on wheels (leveling)

- Reducing derailments risk, especially on twisted track and at low speed

- Verifying the distribution of traction on driving wheels

- Verifying the distribution after installation of new equipment on the rolling stocks

- Verifying the distribution of the vertical forces due to non-uniform wear of the wheel diameters or faulty suspensions

- Verifying load distribution on cargo railcars

- Post derailment investigations

- Calibration and on-site verification of dynamic weighing systems compliant with the EN 15654-1, according to EN 15654-3

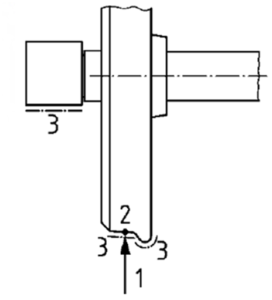

LOCATION OF MEASURING POINTS

As specified in EN 15654-2:2019 at the paragraph 4.2.3.2: “The contact points between the vehicle wheels and the measurement devices are usually on the wheel tread profiles at/or near to the reference points shown in Figure 3. Other contact points on the wheel flange or on the axle box can be used. In these cases, QF0 (the vertical wheel forces at the reference points) shall be calculated from the measured values taking into account the difference between the location of the contact point and the reference point”.

POWERVE® performs measurements directly near to the reference points. It directly determines the QF0, without any additional uncertanties, contrary to the measurements on the wheel flange or on the axle box.

Key

1. Vertical wheel force QF0

2. Reference point D0

3. Possible locations of contact point (running surface, flange, axle box) for measurement device

MEASUREMENT PERFORMED DIRECTLY NEAR TO THE REFERENCE POINTS - NO ADDITIONAL UNCERTAINTIES!

This is made possible by the special load cells of the POWERVE® system, developed and produced by IVM, which are not affected by the transversal components and allow to directly measure the QF0s near the reference point, as required by EN 15654-2. With POWERVE®, the end user directly obtains the real measurement of the needed QF0s. Therefore he does not have to carry out complex calculations to determine the QF0 starting from the measurement on the wheel flange or on the axle boxe (that is a complex operation especially if performed for maintenance, when the wheels are worn differently).

MEASUREMENT ACCURACY ALSO TESTED IN OPERATING CONDITIONS

The system accuracy was determined not only under laboratory conditions, but also under field operating conditions. The accuracy of the sensing elements, that was tested in the laboratory, includes the following values:

Capacity

15 tons/wheel – 30 tons/wheelset

Maximum Safe Load (lim)

30 tons/wheel

Class of the cell (sensor)

Class 1 according to the UNI EN ISO 376:2011 – Accuracy < 0,1%

Class of the pair

Class 0,5 as per ISO 7500-1 according to the Test Procedure specified in the EN 15654-2:2019

The accuracy of the whole system that was tested in the field and in operating conditions is:

0,5% ON THE TOTAL WEIGHT

AWARDED BY

System description

The POWERVE® system is extremely modular and scalable because it measures from 2 to 6 wheelsets at the same time, depending on the measuring necessities. It is constituted by 2 main functional Kits:

Wheelset Kit

Control System

The Wheelset Kit includes the mechanical parts and the sensing elements with the dedicated acquisition boards, needed to measure each single wheelset.

The Control System includes the execution and control elements, needed to manage the measuring process. The Control System allows to control any Wheelset Kit, without configurations needed. Moreover it also includes a Cloud platform, to manage and download all the measures in the most common formats (PDF, Excel, CSV).

The commercial configurations of the POWERVE® system are:

- POW2X made of 2 Wheelset Kits (each one measures the vertical forces of each wheel of a wheelset at the same time) and 1 Control System.

- POW3X made of 3 Wheelset Kits and 1 Control System

- POW4X made of 4 Wheelset Kits and 1 Control System

- POW6X made of 6 Wheelset Kits and 1 Control System

THE ROLLING STOCK RISES EASILY

The rolling stock to be measured can be easily moved on the ramps by using a shunting vehicle (electric or diesel), a locomotive or just by using a couple of winches.

Minimum slope of the ramps: 42,3‰

IS YOUR TRACK LENGTH LIMITED?

No problems!

The measurement procedure requires moving the rolling stock by just 1 meter during the operation as opposed to fixed systems which require at least twice the train length.

So, it is perfect also for small workshops where the length of leveled tracks is limited.

IT FITS ANY RAIL PROFILE

It can be easily installed on different ranges of rail profiles. Customized rail profiles ranges might be available under request.

HUMAN INDEPENDENT RESULTS

POWERVE® is equipped with several checks and visualization systems to control the measurement (Auto-Quality Checks, including AutoDiagnostics), also aimed to limiting human errors.

THE LIGHTEST RAILWAY WEIGHING SYSTEM EVER!

Hand-transportable everywhere, also by airplane (about 25 kg for each Wheelset Kit split in 2 cases). Heaviest single part of just 6,3 kg.

WIRELESS CONNECTION

Each Wheelset Kit connects via wireless technology. This allows for easy installation and simple operation.

TIME SAVING

The operation is very efficient and time saving! The installation of the ramps and the sensing elements takes just a few seconds, without any mechanical fixing!

USER FRIENDLY SOFTWARE

POWERVE® is supplied with the POWERVE® Control System software, an Android app directly installed on the tablet.

The Control System is a full software package, very user-friendly, designed to support the operator and to guide him during the whole measurement cycle.

TRACK GAUGE INDEPENDENT

The system is gauge independent.

The ramps can be installed also on the multiple gauges tracks, without limitations.

SMART CLOUD PLATFORM

The POWERVE® Control System was not only designed just for easy data collection in the field. The system is fully digitalized and it is equipped with a dedicated Smart Cloud Platform, where the operator can easily manage and compare the measurements over the time.

CALIBRATION PERIOD: DISCOVER THE COURTESY KITS

The calibration period or any system fault always determines the unavailability of the system and impacts on the customer’s activities and his productivity. In order to fully support the customer and to guarantee a full availability of the system even during the calibration

period/faults, a temporary Courtesy Kit is provided to the customer before to ship the system to be calibrated. The Courtesy Kit replaces only the parts to be calibrated (Acquisition Boards and the related Load Cells). It consists of the same quantity of Wheelset Kits to be calibrated/ fixed in order to fully cover the measuring necessities.

CO-FINANCED BY

POWERVE® is co-financed by the European Union, by the Italian State and by the Region of Campania, within the ROP Campania ERDF 2014-2020.