INTRODUCING POWERVE

Certified by ITALCERTIFER – EN 15654-2:2019 and EN 50215:2011 compliant

MEASUREMENT OF THE VERTICAL FORCE DISTRIBUTION ON WHEELS AND WHEELSETS:

FINALLY EASY, FAST, ANYTIME & EVERYWHERE!

The right equalization of the static vertical forces on wheels is a key-factor to ensure the dynamic stability of any rolling stock. Unloaded wheels, especially on the diagonal side of a bogie, can significantly decrease the capacity of the bogie to safely run on twisted tracks, up to derailments.

Due to improper maintenance, abnormal wear/faulty suspensions or abnormal wear of the wheel diameters measured at the wheel tyre level, unloaded wheels can occur many times, resulting in loss of vehicle balance. Thereby dynamic behavior and safety are impacted.

Also from our in-field tests experience (demos and weighing services performed over the years), it emerged that there were unbalanced vehicles in most cases, even during the interval between two heavy maintenance cycles. Therefore the wheel force distribution should be checked with higher frequency.

But how to increase the frequency of the inspections?

It is usually needed a high performance fixed weighing system, capable of performing measurements with huge accuracy, directly at the wheel/rail interface and in perfect stable equilibrium conditions. Unfortunately the right fixed system is not always easy to find nearby. Furthermore moving a rolling stock vehicle to an accurate fixed weighing system (located far away) can be expensive too. As a result, a testing approach like this, aimed at easily and continuously checking the vertical forces on each wheel, is often an expensive and challenging achievement.

How to turn it into a sustainable & optimized solution?

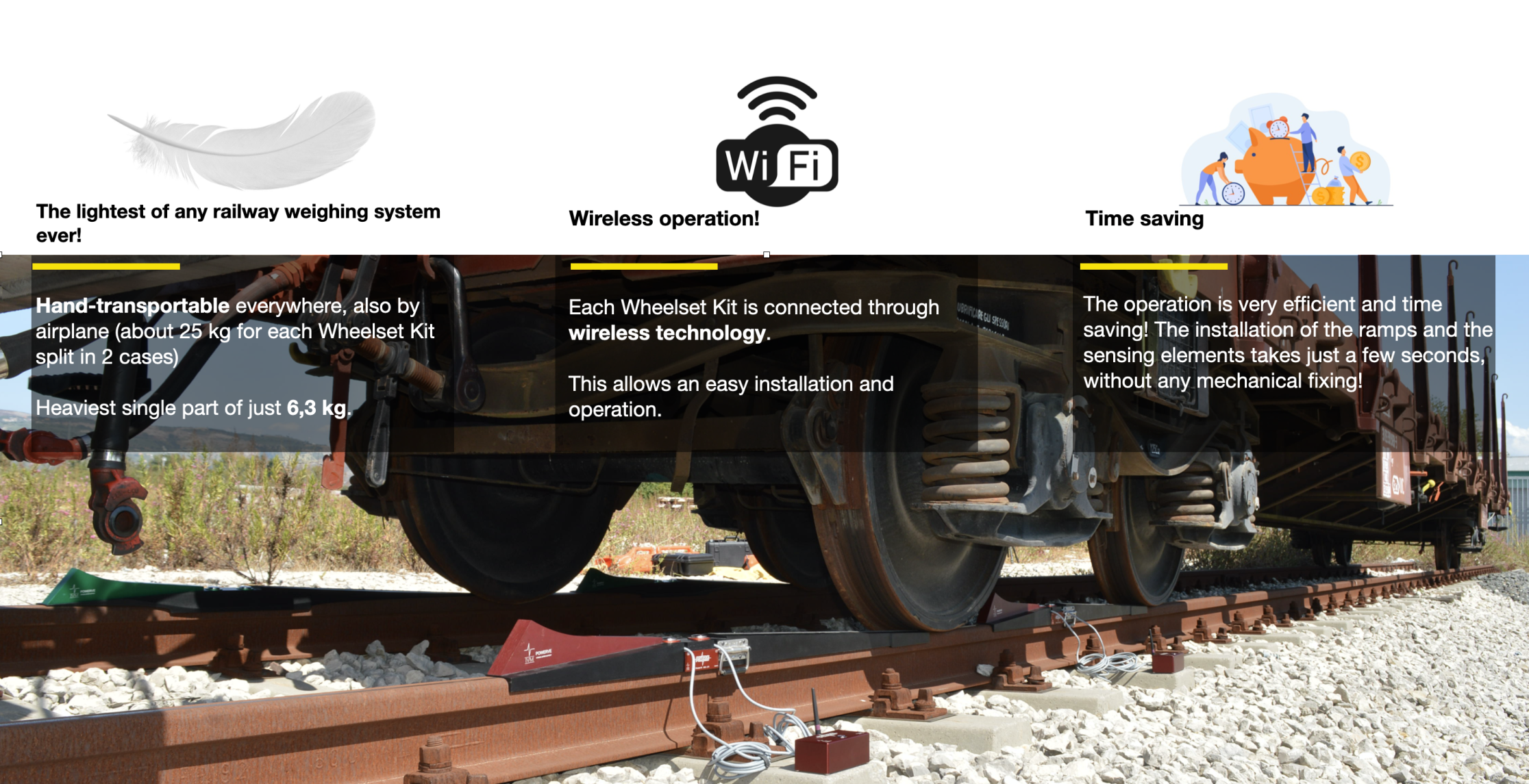

IVM is glad to introduce POWERVE®, the most innovative and hand-portable wheel force measuring system. It is able to statically measure the vertical forces on each wheel and wheelset of any rolling stock type and determine the vehicle’s balance health.

POWERVE® allows to easily perform the measurements mostly anytime & everywhere, preventing derailment risk and improving running dynamics.

THE IDEAL SOLUTION FOR

- Testing & Commissioning of new, maintained or modified rolling stock, compliant with the EN 15654-2:2019

- Workshop or in-field maintenance

- Suspension load adjustment

- Reducing derailments risk, especially on twisted track and at low speed

- Verifying the distribution of traction on driving wheels

- Verifying the distribution after installation of new equipment on the rolling stocks

- Verifying the distribution of the vertical forces due to non-uniform wear of the wheel diameters or faulty suspensions.

- Verifying the distribution on the freight railcars

- Derailment investigations

- In-field calibration and verification for dynamic weighing systems compliant with the EN 15654-1 as prescribed by the EN 15654-3

IMPRESSIVE PERFORMANCES

POWERVE® has been continually improved over the years, achieving impressive performances that are comparable with highly accurate static fixed weighing systems.

The system is able to perform certified measurements, according to the EN 15654-2:2019: “Railway applications – Measurement of vertical forces on wheels and wheelsets – Part 2: Test in workshop for new, modified and maintained vehicles”.

POWERVE® turns every leveled track in a very precise & accurate weighing system that performs the tasks easily and quickly.

More than just a weighing equipment, POWERVE® can be considered a safety equipment for the railway industry, being able to instantly measure the rolling stock’s vertical wheel force distribution and detecting potential unbalancing issues.

One of the most interesting system feature is its ability to directly measure the same wheel force distribution that any rolling stock loads on the track.

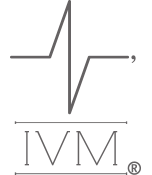

In fact, it measures at the wheel/rail interface (where each wheel loads on the rails) unlike other systems that measure at points which can deliver different results on the distribution.

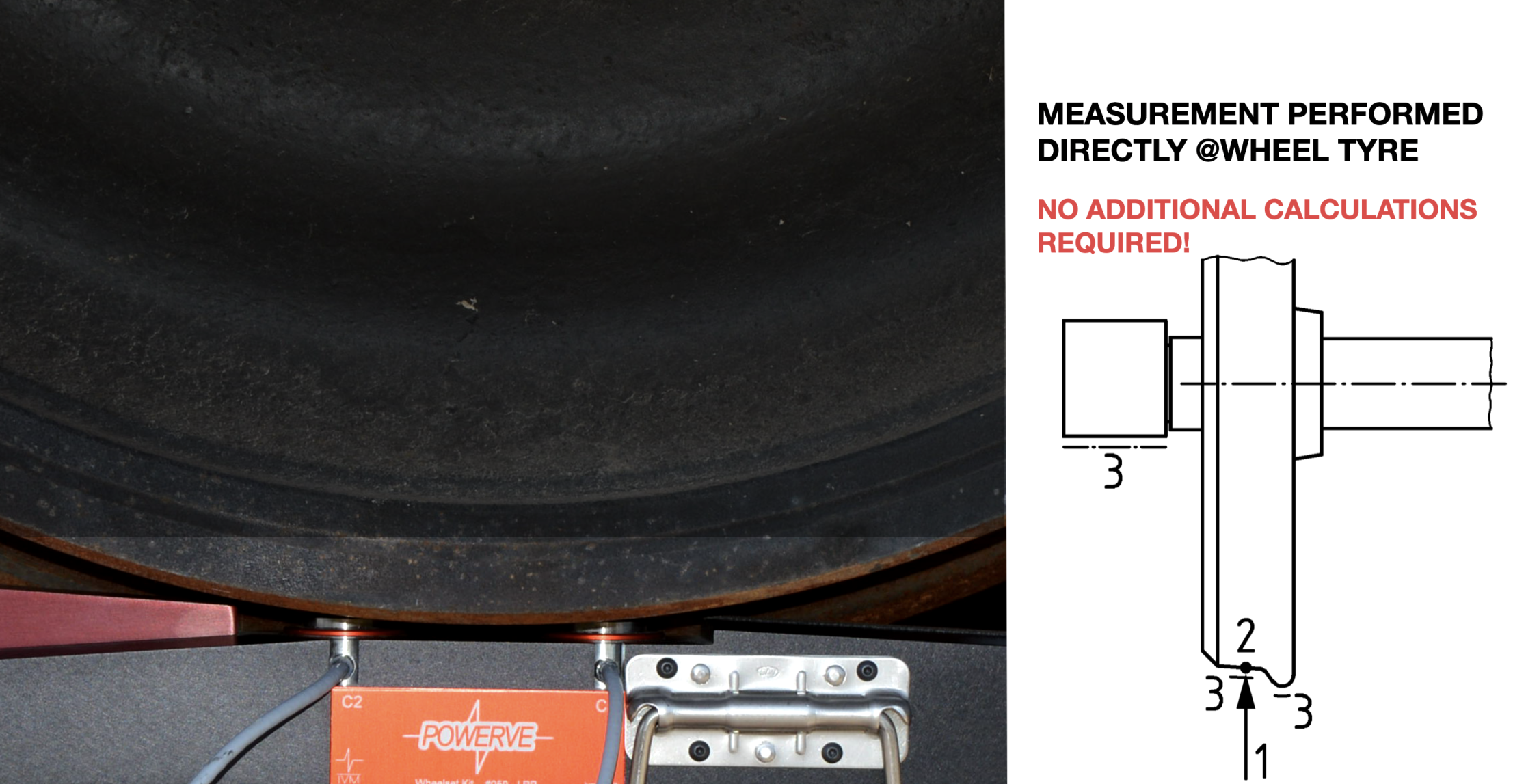

LOCATION OF CONTACT POINTS (Running surface, flange top, axle boxes)

As specified in the EN 15654-2:2019 at the paragraph 4.2.3.2: “the contact points between the vehicle wheels and the measurement devices are usually on the wheel tread profiles at/or near to the reference points. Other contact points on the wheel flange or on the axle box can be used. In these cases, QF0 (the vertical wheel forces at the reference points) shall be calculated from the measured values taking into account the difference between the location of the contact point and the reference point”.

POWERVE® performs measurements directly near to the reference points. It directly determines the QF0, without any additional and complex calculations, contrary to the measurements on the wheel flange or the axle box.

MEASUREMENT PERFORMED DIRECTLY @WHEEL TYRE

NO ADDITIONAL CALCULATIONS REQUIRED!

UNIQUE “CRADLE” DESIGN

Thanks to the unique “cradle” design of the measuring area, made of two load cells for each wheel, the rolling stock stays still on the measuring zone in self-equilibrium condition. There is no need to stop the train on the system and possible errors due to braking/traction forces are avoided.

The system measures the true distribution of each wheel vertical force on the track, at the wheel/rail interface and in working order conditions, without modifying the natural status of the suspensions.

MODULAR & SCALABLE

The POWERVE® system is extremely modular and scalable. It measures from 2 to 6 wheelsets at the same time, depending on the measuring necessities. It is constituted by 2 main functional Kits:

- Wheelset Kit

- Control System

The Wheelset Kit includes the mechanical parts and the sensing elements with the dedicated acquisition boards, needed to measure each single wheelset.

The Control System includes the execution and control elements, needed to manage the measuring process. Moreover it also includes a Cloud platform, to manage and download all the measures in the most common formats (PDF, Excel, CSV).

The commercial configurations of the POWERVE® system are:

– POW2X – made of 2 Wheelset Kits (each one measures the vertical forces of each wheel of a wheelset at the same time) and 1 Control System.

– POW3X – made of 3 Wheelset Kits and 1 Control System.

– POW4X – made of 4 Wheelset Kits and 1 Control

– POW6X – made of 6 Wheelset Kits and 1 Control System.

The POW2X version allows to measure the following rolling stock wheelsets arrangement types, (regardless of whether the wheelsets are driving or trailing):

A (1 single wheelset, in case of trailers) – in 1 measurement session;

A-A (2 single wheelsets) – in 1 measurement session;

B-B (2 bogies made of 2 wheelsets each) – in 2 measurement sessions;

B-B-B (2 frames separated by a coupler, on 3 bogies made of 2 wheelsets each) – in 3 measurement sessions;

The POW3X version allows to measure in addition to the POW2X version, also the following rolling stock type:

A1A or C (3 wheelsets in total) – in 1 measurement session;

C-C (2 bogies made of 3 wheelsets each) – in 2 measurement sessions;

TRACK GAUGE INDEPENDENT

The system is gauge independent. For this reason, the ramps can be installed also on the multiple gauges tracks, without limitations.

THE ROLLING STOCK RISES EASILY

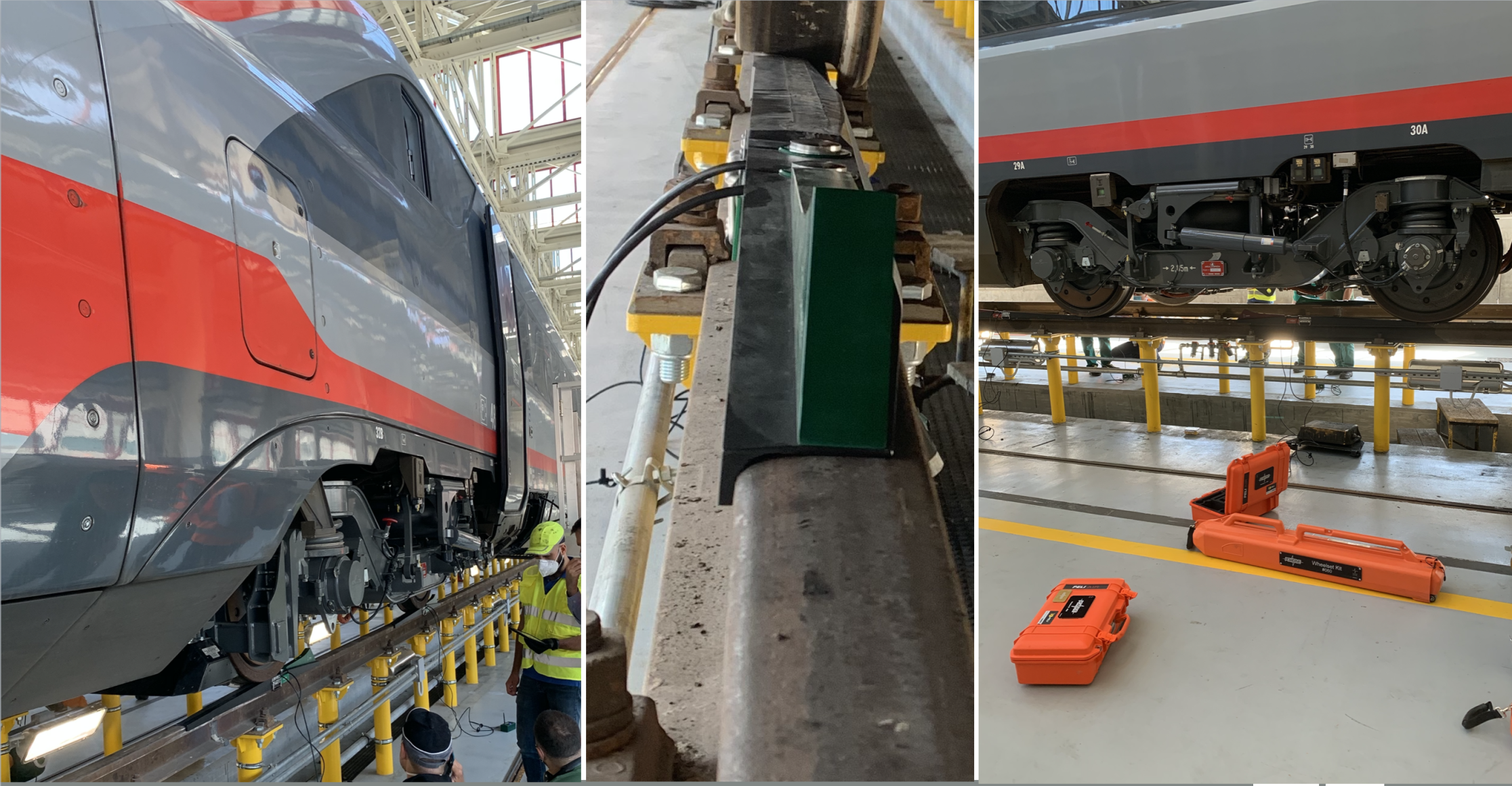

The rolling stock to be measured can be easily moved on the ramps by using a shunting vehicle (electric or diesel), a locomotive or by using a couple of winches.

IS YOUR TRACK LENGTH LIMITED?

No problems!

The measurement procedure requires moving the rolling stock by just 1 meter during the operation as opposed to fixed systems which require at least twice the train length.

So, it is perfect also for small workshops where the length of leveled tracks is limited.

IT FITS ANY RAIL PROFILE

It can be easily installed on different ranges of rail profiles. Customized rail profiles ranges might be available under request.

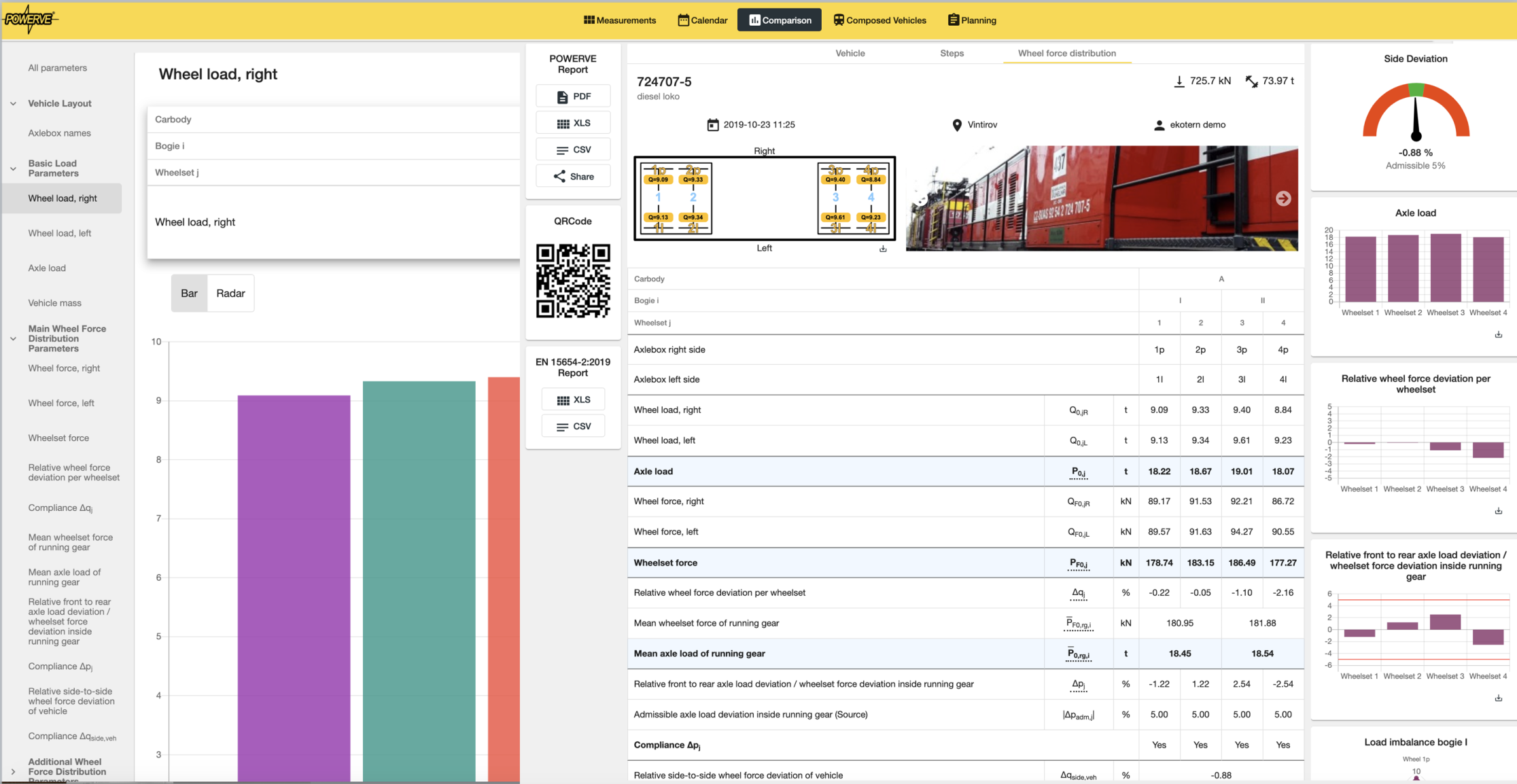

USER FRIENDLY SOFTWARE

POWERVE® is supplied with the POWERVE Control System, an Android app directly installed on the tablet. The Control System is a full software package, very user-friendly and designed to support the operator and to guide him during the whole measurement cycle.

HUMAN INDEPENDENT RESULTS

POWERVE® is equipped with several checks and visualization systems to control the measurement (Auto-Quality Checks, including Auto-Diagnostics), also aimed to limiting human errors.

During the procedure, the system automatically checks if all the measurements are statistically similar to each other. If the values are not consistent, the Tablet application will ask to perform additional measurements, until at least 3 similar satisfactory values are reached.

SMART CLOUD PLATFORM

The POWERVE Control System was not only designed just for easy data collection in the field.

The system is fully digitalized and it is equipped with a dedicated Smart Cloud Platform, where the operator can easily manage and compare the inspections over the time.

So, it provides a clear balance state of the entire vehicle fleet over the time, finally unlocking 4.0 predictive maintenance approaches.

ANY CONCERN ABOUT THE SYSTEM UNAVAILABILITY? DISCOVER THE COURTESY KIT!

The calibration period or any system fault always determines the unavailability of the system and impacts on the customer’s activities and his productivity.

So, in order to fully support the customer and guarantee a full availability of the system even during the calibration period/faults, a temporary Courtesy Kit is provided to the customer before shipping the system to be calibrated.

The Courtesy Kit replaces only the parts to be calibrated (Acquisition Boards and the related Load Cells). It consists of the same quantity of Wheelset Kits to be calibrated/fixed in order to fully cover the measuring necessities.

For any inquiry, please write to info@ivmtech.it