The importance of measuring the distribution of vertical forces per wheel in static conditions for maintenance

To monitor an evolving system means the control of the performance of one or more parameters related to it that may vary over time. In the technical-scientific field, the purposes of monitoring can be different and divided into:

- Analysis of the physical phenomena associated with the system in order to identify the laws that can describe them;

- Identification of causes that have determinate particular situations of the system and identify possible corrective actions.

In this second case, the diagnostic objective is typically functional or preparatory to maintenance interventions. In the railway sector, considering a bogie resting on the track, one of the objectives of the diagnostic is to monitor the distribution of the load exerted by the wheels on the rail.

This leads to identify conditions in which the distribution deviates from the design and/or regulated values and therefore an intervention is required. At the same time, it means identifying the possible causes that generated the aforementioned conditions. Among these, for example, there may be a degradation of the stiffness of the suspensions and / or of the geometry of the frame.

In order to be able to study the physical phenomenon of degradation also with statistical methods so as to identify the laws and the parameters that influence it, the monitoring should be able to measure the parameters chosen with adequate accuracy and temporal frequency to describe the evolution and to identify in time a deterioration that urgently requires maintenance intervention.

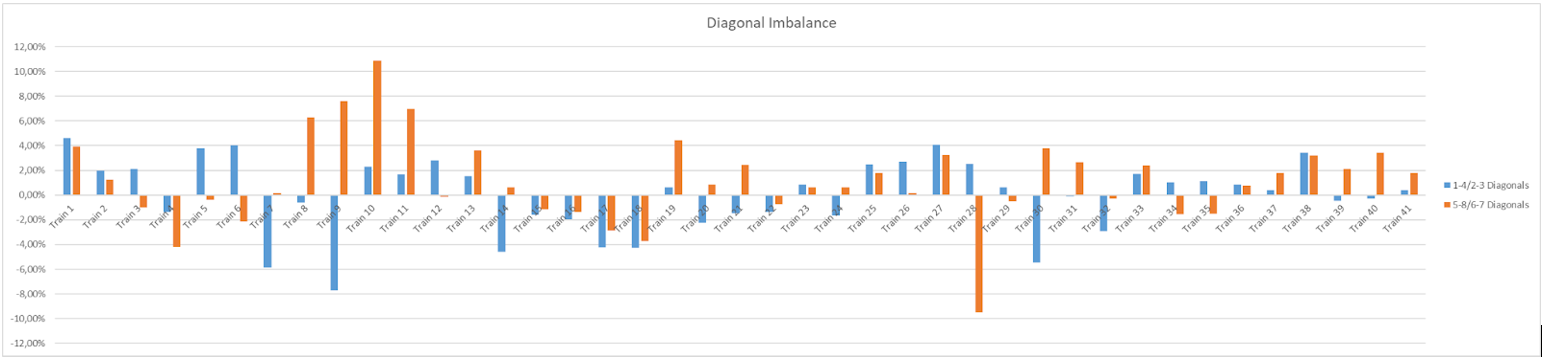

The following histogram shows the results of a monitoring, performed on a certain number of two-bogie rolling stocks, of the imbalance of the related wheelsets.

All the examined bogies present at least one unbalanced wheelset of more than 5% and consequently present an imbalance of the diagonals.

As shown with the Bogie Playground, this condition is a sign of non-uniform stiffness of the primary suspensions or of twisted bogie. Both of these situations require maintenance.

These measurements are accurate enough to detect the presence of the imbalance, but are not frequent enough to determine when these conditions have occurred. It’s only known that these measurements were performed during the interval between two successive cyclical maintenance.

Therefore, in order to determine the evolution of the degradation phenomenon, it is necessary to measure several times to understand when the phenomenon started and especially if it is related to some triggering event. This information could be very useful both to improve maintenance and to identify causes.

However, we must introduce another factor which can affect the monitoring and can be summarised in: complexity of carrying out the measurement, associated with cost and time.

From this point of view, POWERVE® represents a breaking point since it can reduce cost and time.